At RMS3Dsolution, we bridge the gap between complex design and large-scale production. Our facility utilizes cutting-edge technologies including VMC machining, injection molding, laser cutting, and sheet metal fabrication to deliver high-volume orders with uncompromising precision.

By integrating advanced robotics and streamlined workflows, we ensure every unit meets rigorous quality standards while accelerating your time-to-market. Whether you are scaling a prototype or managing a full product launch, RMS3Dsolution provides the reliability and efficiency your brand deserves.

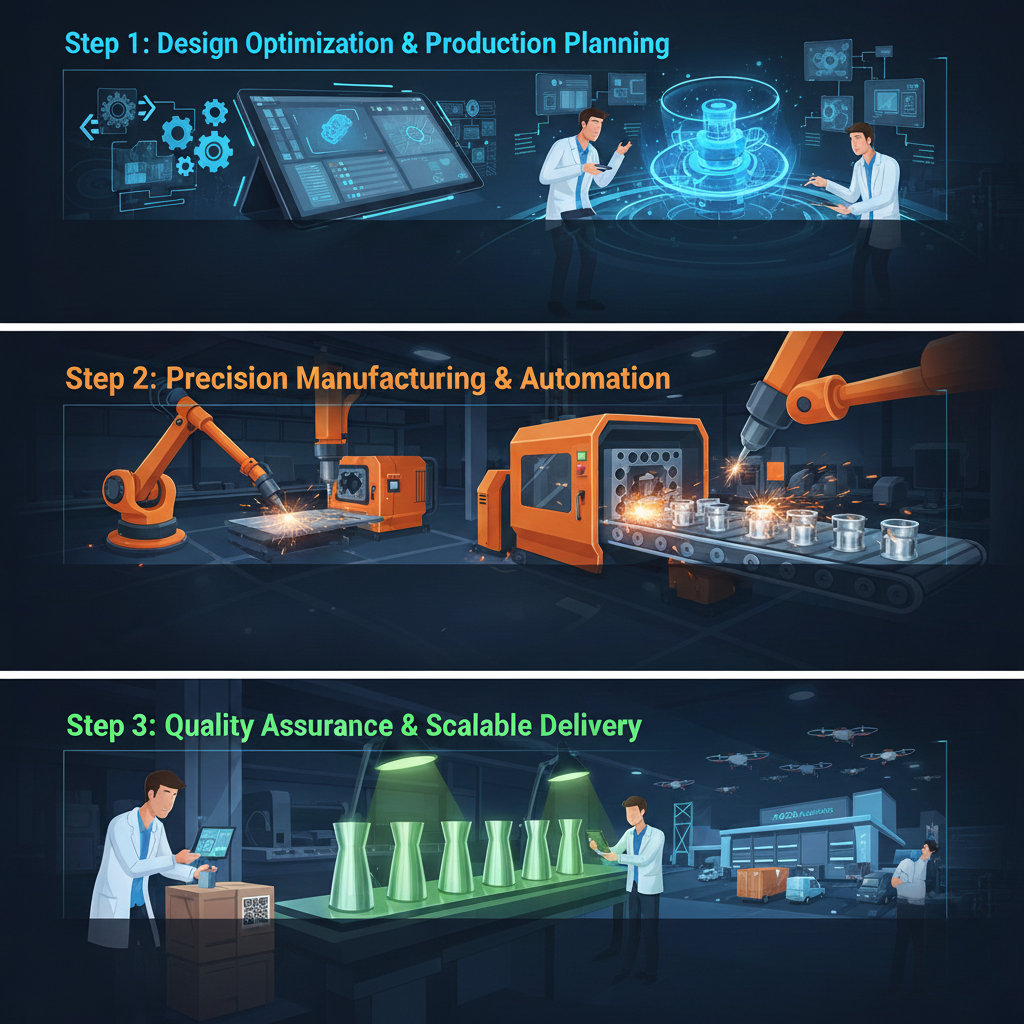

Our Mass Manufacturing Process :–

Step 1: Design Optimization & Production Planning

We optimize your design for manufacturability, scalability, and cost efficiency to ensure accurate, production-ready outcomes.

Step 2: Precision Manufacturing & Automation

Advanced machining and automated systems enable consistent, high-volume manufacturing with tight tolerances.

Step 3: Quality Assurance & Scalable Delivery

Strict quality checks and scalable production ensure reliable, on-time delivery from pilot runs to full launches.